| |

A process-reliable, stable material feed, combined with the efficient cooling of the tools and the targeted Washing away emerging chips,

forms the basis for a optimal use of the lathe.

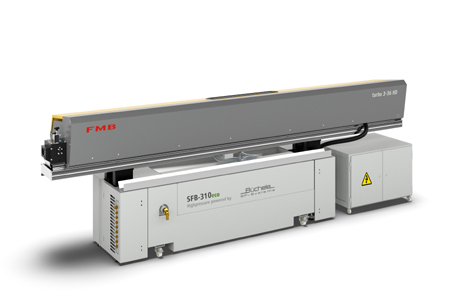

The FMB turbo 3-36 HD / SFB-310eco combines these Requirements

in especially user-friendly and space saving form.

The connection of the proven FMB loading magazine technology with

the innovative and energy-efficient high-pressure technology from

SF-Systeme Büchele in a compact unit, sets new ones Standards in operability and application.

Suitable for machine tools, short and long lathes.

|

|

Max. performance

|

Filtration

|

Filter area

|

Tank capacity

|

Operating voltage

|

Power requirement

|

|

100 bar / 28 l/min

|

40 μm

|

6370 cm²

|

200 l

|

400 V

|

7 kW

|

|

150 bar / 24 l/min

|

40 μm

|

6370 cm²

|

200 l

|

400 V

|

9 kW

|

Technical data turbo 3-36 HD für Stangendurchmesser von 3-38 mm:

| |

Unit

|

turbo 3-36 HD

|

|

Vorschubstangen-Ø (max.)

|

mm |

38

|

|

bar length

|

mm |

3200 |

|

bar diameter-Ø (min.-max.)

|

mm |

3 - 38

|

|

Loading capacity

|

mm |

200 |

|

Loading capacity (min.Ø / max.Ø)

|

St. |

66 bei 3mm / 5 bei 38mm

|

|

Remnant piece length (max)

|

mm |

450 |

|

Loading time (ca.)

|

s |

26 |

|

Feed speed

|

mm/s |

0 - 700

|

|

Operation voltage (50/60 Hz)

|

V |

3x 190 - 480

|

|

Power requirement

|

kW |

1,5 |

|

Compressed air connection

|

Mpa (bar)

|

0,6 (6) |

|

Weight without oil filling

|

kg |

750 |

• Medium: Cutting oil, aqueous emulsion (min. oil content 8%)

• Changeover filter (rinsable wire mesh)

Options:

• up to 8x valve switching

• 10 μm filter for deep hole drillling

|