|

Applications:

Ideal for: Steel, free cutting steel, tool steel, non-ferrous metals, stainless steel

Suitable for: Aluminium, magnesium, brass

Advantages:

- Low life-cycle costs, as there is no need to replace filter material

- Cleaning without interruption in filtration

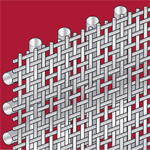

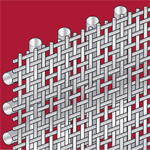

- Precision chip removal based on principle of surface filtration

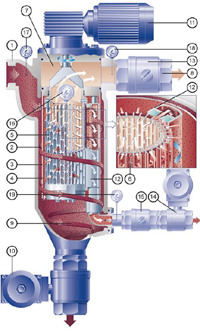

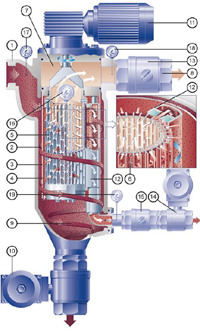

- Top-quality asymmetric filter medium made from

multiple sintered stainless steel mesh on sturdy support body

- Process safety thanks to efficient filter cleaning

- Solid construction and high-grade materials for prolonged service life

- Low liquid loss during cleaning process

- Segment-based filter cleaning with powerful backwashing pulse

- Specification of actual filter size and nominal chip removal rate

- Integrated preliminary chip removal by means of tangential inflow and immersion tube

- Material combinations for wide range of applications

- Low-maintenance design

Requirements:

- Preliminary chip removal in interstitial strainer/basket strainer > 2 mm or chip conveyor

- Applications: Drilling, milling, turning

- Medium: 8 - 32 mm²/sec

- Rated flow rate: 60 - 80 l/min for steel machining

We recommend using only filtered oil in the machine. At particle loads of more than

200 mg/l, the oil should be cleaned first in a separate filtration unit. As a rule, the

total particle load of the oil should not exceed 200 – 300 mg/l.

For retrofitting, the entire cooling lubricant system must be cleaned of all chips and fine xxx dirt particles.

|

Automatic back flush filter

Topmesh

|